Slide 1

INTRODUCING THE

LINEMASTER X

The most advanced automated beer line cleaning system in the World!

Slide 1

INTRODUCING THE

LINEMASTER

X

X

The most advanced automated

beer line cleaning system in the World!

Slide 1

EASY

TO USE

TO USE

Even during

working hours

QUICK CLEANING CYCLE

On one or

multiple lines

WASTE SAVING OPTION

Save up to 100% of

manual cleaning waste

VERIFIABLE RESULTS

Using our color

change technology

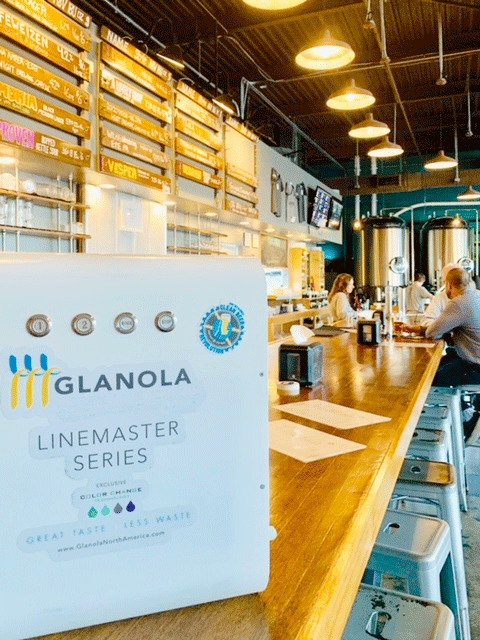

The innovative and patented Linemaster X can now be found in draft bars throughout the country, be they taverns, restaurants, breweries, entertainment centers, country clubs, hotels, and even cruise ships - ensuring a great taste and reduced waste.

So what are you waiting for - Join the Clean Beer Revolution!

Slide 1

OUR COMPANY

Slide 1

Glanola believes strongly in the philosophy of making life simple through innovation. As a result, a large portion of our budget goes into research and development. Our systems are built to last with new improvements and complimentary products constantly in development.

Glanola is leading the way bars can offer a ‘consistently authenticate’ taste and reduce or even eliminate waste!

Glanola is leading the way bars can offer a ‘consistently authenticate’ taste and reduce or even eliminate waste!

See what our customers think!

Winner of the Irish Echo

Small Business Big Impact Award

Small Business Big Impact Award

Winner of the Irish Pubs

Global Innovation Award

Global Innovation Award

Slide 1

THE SYSTEM

GREAT TASTE

-

LESS WASTE

GREAT TASTE | LESS WASTE

Glanola

The Appliance of Science

The Appliance of Science

The Linemaster X allows the bar owner / operator to efficiently clean lines – individually or grouped – as often as they wish in an efficient and none intrusive manner (even during working hours!) while conforming to all new regulatory requirements. The system also offers the bar owner invaluable reporting features which can be customized to meet their own specific needs. The result of which is significantly reduced waste and vastly improved quality leading to greater sales / profitability, not to mention an increased understanding of their operations leading to greater piece of mind.

Glanola's proprietary detergent will change color (from purple to green) in the presence of bacteria. It will change back to purple once the line is clean, thus giving you peace of mind - can your lines be seen to be clean?

THE PROOF

Upon request, a Glanola technician will test your beer lines with a state-of-the art Kikkoman bacteria measurement tool, before and after a clean, to illustrate the effectiveness of the Linemaster X.

Slide 1

CONTACT

Ready to see the system in action? Looking to partner with us?

Slide 1

Glanola, Inc.

6 Perkins Way, Unit H

Newburyport, MA 01950

Office: 978-462-4000

Fax: 978-462-4008

Toll Free: 1-855-452-6652

info@glanola.com

Glanola is a proud member of

the Brewers Association.

Glanola, Inc.

6 Perkins Way, Unit H

Newburyport, MA 01950

Office: 978-462-4000

Fax: 978-462-4008

Toll Free: 1-855-452-6652

info@glanola.com

Glanola is a proud member of

the Brewers Association.